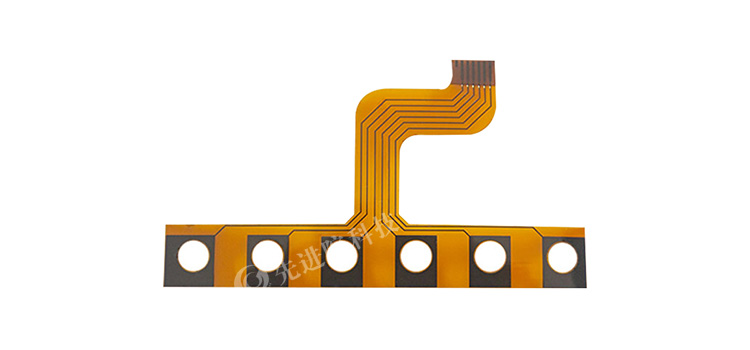

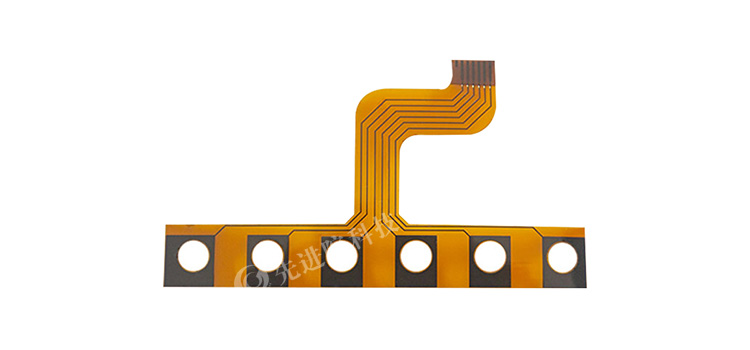

Industrial sensor FPC flexible board is a printed circuit board made of flexible substrates, which has high flexibility and bendability, and can adapt to complex and changing industrial environments. It is mainly used to connect circuits between industrial sensors and control systems, to achieve signal transmission and data processing.

main features

- Flexible Connection: FPC flexible board has good flexibility and can be bent and folded freely, adapting to narrow spaces and complex three-dimensional structural designs, ensuring stable connection between sensors and control systems.

- Lightweight and portable: FPC soft board substrate is lightweight and helps reduce product weight and thickness, improving the portability and flexibility of industrial equipment.

- High reliability: Using advanced manufacturing processes and materials, FPC flexible boards have excellent electrical performance and mechanical strength, and can withstand complex conditions such as vibration and temperature changes in industrial environments, ensuring stable signal transmission.

- High density wiring: FPC flexible board can achieve high-density wiring, reduce interference between circuits, and improve the stability and reliability of signal transmission.

- Easy to install and maintain: The flexible nature of FPC boards simplifies the installation process, reduces installation difficulty, and facilitates maintenance and replacement.

application area

Industrial sensor FPC soft boards are widely used in various industrial fields, including but not limited to:

- Automated production line: used to connect sensors and actuators to achieve automated control.

- Industrial detection system: used to connect sensors and data acquisition systems to monitor the real-time operation status of industrial equipment.

- Environmental monitoring system: used to connect temperature sensors, humidity sensors, etc., to monitor environmental parameters.

- Intelligent Manufacturing: In intelligent manufacturing systems, FPC boards serve as a bridge between sensors and control systems, enabling intelligent control and data acquisition.

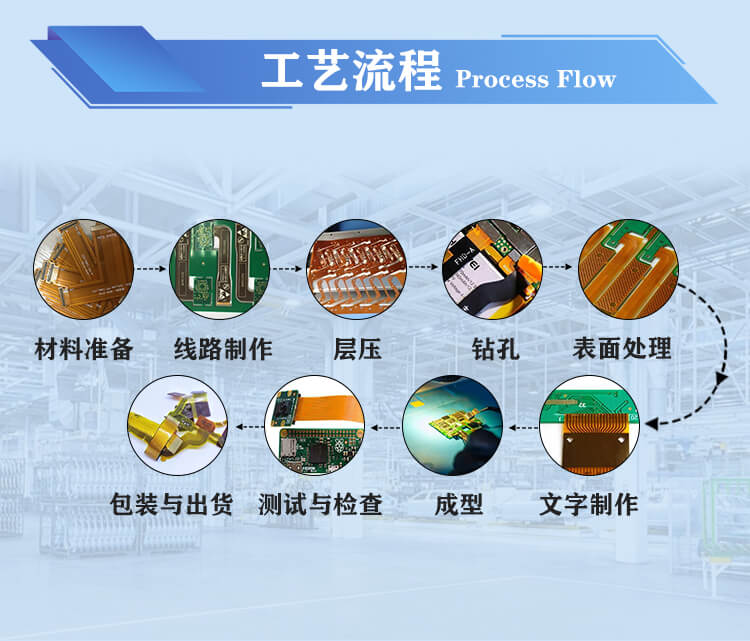

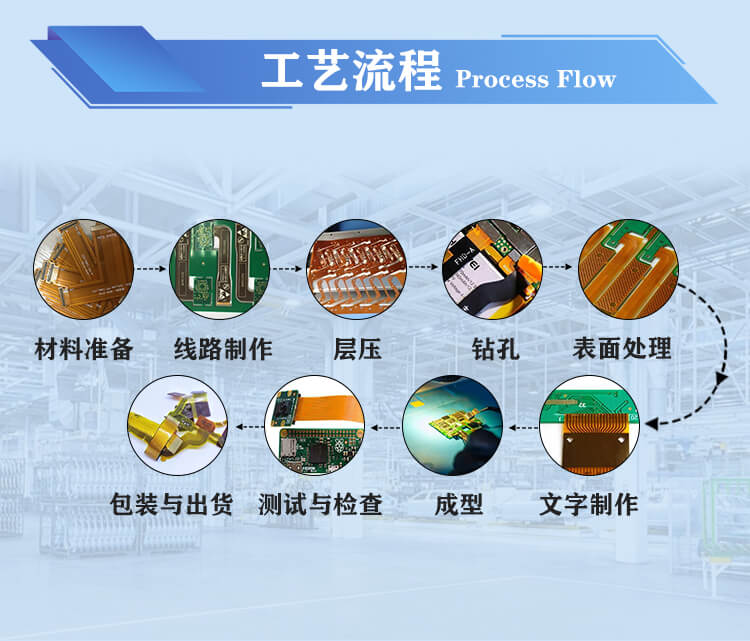

Manufacturing process and materials

- Manufacturing process: The manufacturing process of industrial sensor FPC soft board includes material preparation, circuit fabrication, lamination, molding, and testing. Among them, circuit fabrication is a key step, forming circuit patterns through processes such as photolithography and etching.

- Main materials: The main materials of FPC flexible board include insulating substrates (such as polyimide PI, polyester PET, etc.) and copper foil. The insulating substrate has good insulation performance and mechanical strength, while copper foil is used to form conductive lines. In addition, auxiliary materials such as covering film and adhesive film are also required.

Precautions for use and maintenance

- Usage environment: Ensure that the FPC flexible board is used within the specified temperature, humidity, and vibration range, and avoid prolonged exposure to harsh environments.

- Installation and connection: During the installation and connection process, it should be ensured that the FPC flexible board is not excessively bent, stretched, or compressed to avoid affecting its performance and lifespan.

- Regular inspection and maintenance: Regularly inspect and maintain the FPC soft board, promptly identify and address potential issues, and ensure its stable operation.

In summary, industrial sensor FPC soft board is a high-performance and highly reliable electronic component widely used in various industrial fields. By selecting appropriate manufacturing processes and materials, as well as proper usage and maintenance methods, it can ensure stable operation and long-term use in industrial environments.