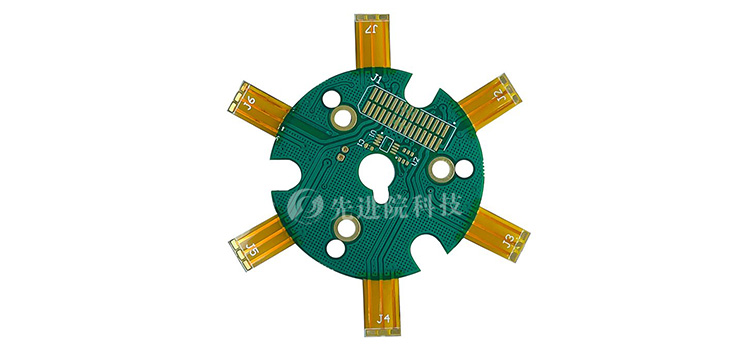

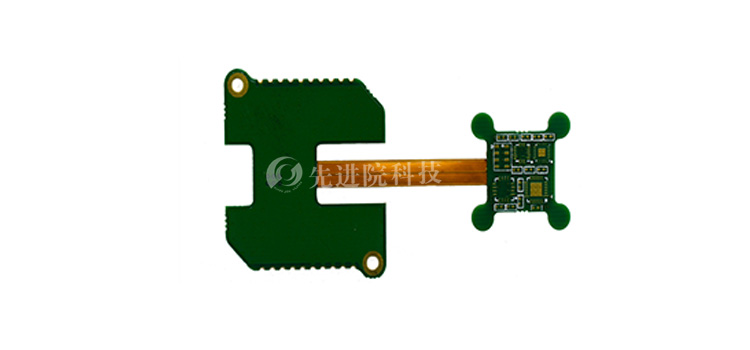

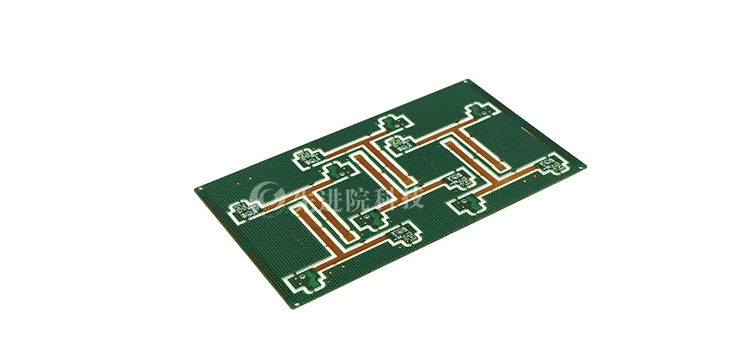

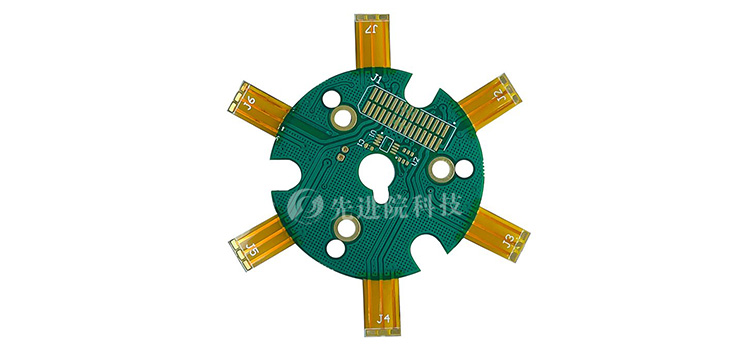

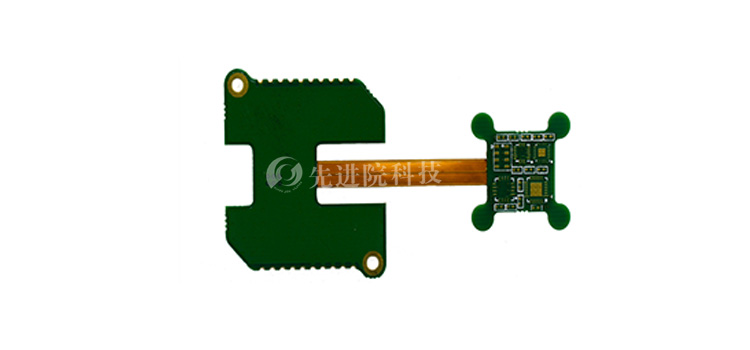

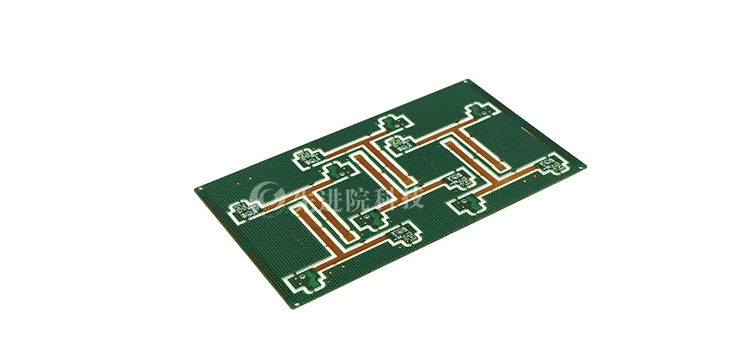

FPC flexible board is made by using optical imaging pattern transfer and etching technology on a flexible substrate surface to create conductor circuit patterns. The surface and inner layers of double-sided and multi-layer circuit boards are electrically connected through metalized holes, and the surface of the circuit pattern is protected and insulated by PI and adhesive layer. It is mainly divided into various types such as single panel, double-sided panel, multi-layer panel, and soft hard combination panel to meet the needs of different industrial control panels.

Product Features

- Small size and light weight: FPC flexible board greatly reduces the size of devices and is suitable for the development of electronic products towards high density, miniaturization, lightweight, thinning, and high reliability.

- Flexibility: FPC flexible board can be freely bent, wound, and folded, and can withstand millions of dynamic bends without damaging wires. It can expand into three-dimensional space, improving the freedom of circuit design and mechanical structure design.

- Excellent electrical performance: FPC flexible board has good conductivity and dielectric properties, which can meet the signal transmission needs of complex electronic products.

- High heat resistance and stability: FPC flexible board is made of special materials, which have excellent high temperature resistance and stability, suitable for working in harsh environments.

- High assembly reliability: FPC flexible board has high assembly reliability and operability, which easily ensures circuit performance and reduces overall cost.

Main materials

- Substrate: The substrate of FPC flexible board is generally made of flexible materials such as polyimide (PI) or polyester (PET), which have excellent insulation performance and mechanical strength.

- Cover film: The cover film is used to protect the conductor part of the circuit and is composed of organic chemical plastic film and adhesive.

- Adhesive film: Adhesive film is used for interlayer bonding and insulation of multilayer boards, consisting of substrate film and adhesive.

- Copper foil: Copper foil is the main material for conductive circuits, and its thickness and specifications can be customized according to customer needs.

application area

FPC soft boards are widely used in various applications that require flexible connections and complex wiring in industrial control panels, such as automotive electronic control systems, medical equipment, aerospace, industrial control, and other fields.

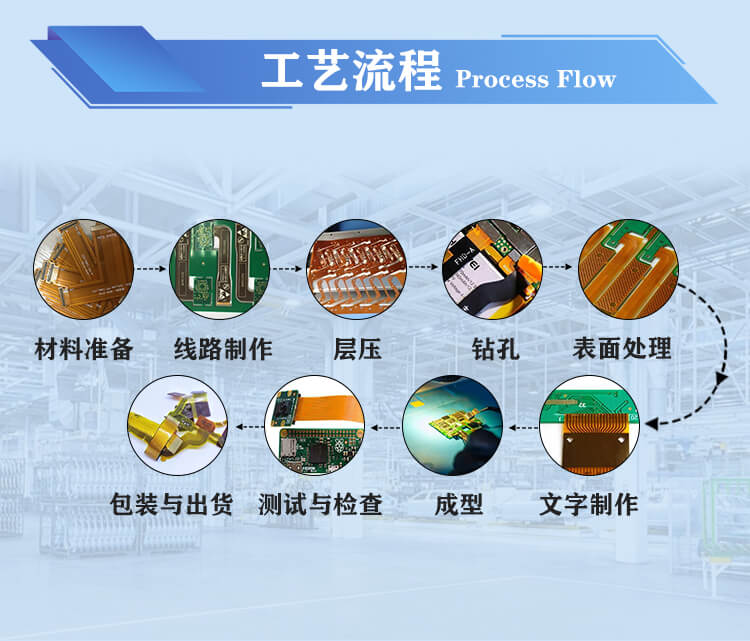

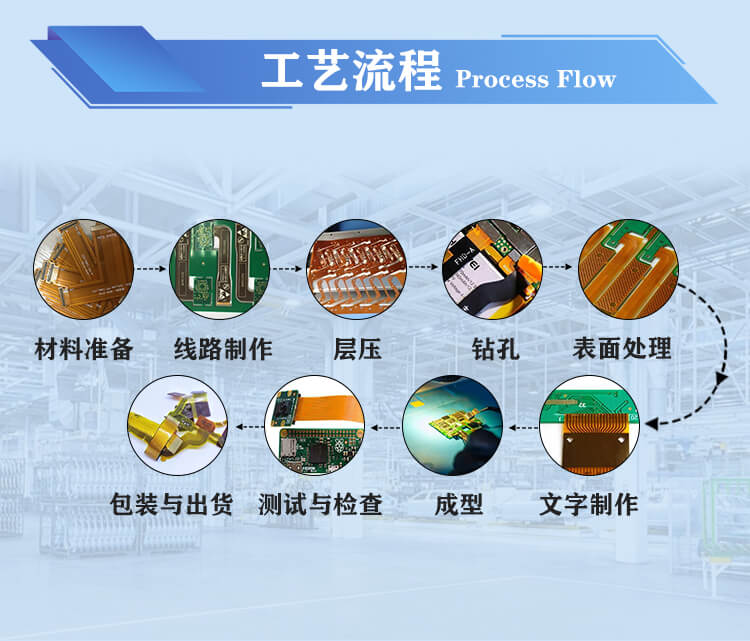

manufacturing process

- Substrate selection: Choose the appropriate substrate according to customer needs.

- Thin film copper-clad coating: A copper layer is covered on a thin film by chemical copper plating or electroplating.

- Graphicization: Forming circuit patterns through processes such as photolithography and etching.

- Assembly and testing: Install the components onto the FPC and conduct electrical performance testing and reliability verification.

The FPC soft board in industrial control panels has the characteristics of small size, light weight, flexibility, excellent electrical performance, high heat resistance and stability, and is one of the indispensable components in electronic products.