Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

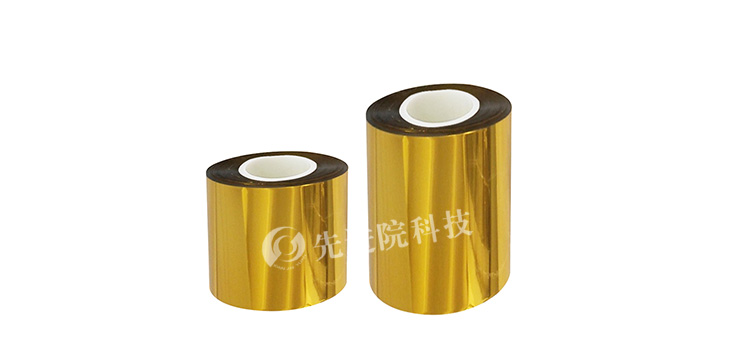

PI, as a high-performance polymer, is renowned for its excellent heat resistance, mechanical strength, and electrical insulation properties. When combined with a metallographic structure with good conductivity and corrosion resistance, the formed composite structure can meet the requirements of harsh environments. However, since PI itself is aNon-polar polymer materialsIts surface energy is relatively low, which makes it difficult for the gold layer to adhere to it. Therefore, exploring effective ways to improve this situation is crucial for promoting technological innovation in related fields.

In order to improve the adhesion of the gold layer on PI, it is necessary to first perform appropriate pretreatment on the surface of PI. Traditional methods include plasma treatment, ultraviolet irradiation, and chemical etching. These methods can remove surface pollutants and increase surface roughness, thereby creating more favorable conditions for subsequent metal deposition. In addition, laser texturing or sandpaper polishing can be used to physically alter the surface morphology of PI, in order to enhance the mechanical biting force between the gold layer and the substrate.

In addition to directly gilding the PI, introducing an intermediate layer is also an effective strategy.PI gold-plated filmBefore gold plating, a layer of titanium (Ti) or chromium (Cr) should be applied first. These two metals not only have good adhesion properties, but also serve as barriers to prevent the diffusion of the gold layer into the PI substrate. According to literature reports, in some cases, aluminum oxide (Al ₂ O3) or yttrium oxide (Y ₂ O3) may also be chosen as buffer layers, which can also help improve the quality of the final product.

Optimizing various parameters involved in the electroplating process, such as current density, solution pH value, temperature, etc., is also crucial. Appropriate parameter settings can not only guarantee the quality of the coating, but also reduce the incidence of defects, indirectly promoting the improvement of adhesion. For example, reducing the current density appropriately can to some extent avoid the problem of internal stress accumulation caused by rapid growth; Meanwhile, maintaining an appropriate operating temperature range is also beneficial for obtaining a more uniform and dense metal coating.

Last but not least, it is essential to strictly control the surrounding environmental conditions, especially humidity levels, throughout the entire manufacturing process. Excessive or insufficient humidity may affect the quality of the coating. For this reason, some advanced production enterprises will adopt constant temperature and humidity workshops to carry out key steps of operation, ensuring the best working environment.

In recent years, Advanced Institute (Shenzhen) Technology Co., Ltd. has beenPI gold-plated filmSignificant achievements have been made in the field. The company focuses on the research and application of new materials, especially in the field of functional thin film materials, and has accumulated rich experience. They have proposed a series of innovative solutions to address the adhesion issues of PI gold plating film, including but not limited to:

Developing new surface modifiers: By synthesizing small molecule compounds with specific structures, the surface properties of PI can be greatly improved without damaging its original characteristics.

Introducing nanoscale fillers: dispersing an appropriate amount of nanoparticles within the PI matrix, which not only does not affect the overall flexibility but also effectively prevents gold atoms from migrating inward.

Design an intelligent production line: By utilizing automated equipment to precisely control every production process, highly integrated management of the entire process from raw material preparation to finished product packaging has been achieved.

In summary, by comprehensively applying the above-mentioned technologies and methods, significant improvements can be madePI gold-plated filmThe adhesion of the surface gold layer meets the needs of different application scenarios. In the future, with the integration of more interdisciplinary knowledge and the emergence of new materials and technologies, it is believed that this field will usher in even broader development space. Advanced Institute (Shenzhen) Technology Co., Ltd. will continue to be committed to the research and development of cutting-edge technologies, providing higher quality products and services for the industry.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2