Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

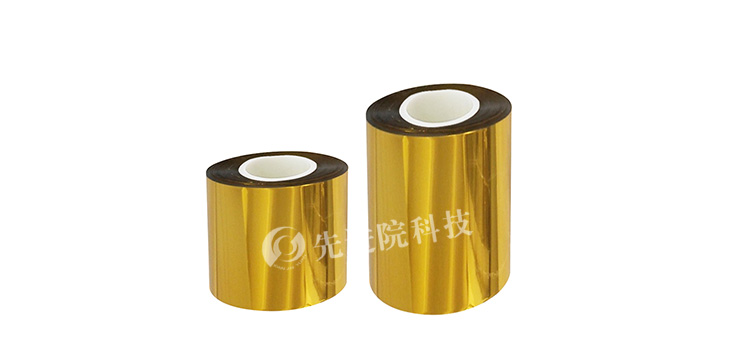

In the rapidly changing field of technology, thin film technology, as a key component of materials science, is constantly driving innovation and development in various industries. Among them,PI gold-plated filmPolyimide gold plating film has become a focus of attention for researchers and engineers due to its unique properties and application prospects. This article will delve into how the thickness and model of PI gold plating film subtly affect its widespread application, revealing the technological secrets and production processes behind it.

PI gold plating film, as the name suggests, is a type of gold plating treatment on the basis of polyimide (PI) filmcomposite materialThe PI film itself enjoys a high reputation in the fields of electronics, aerospace, optics, etc. due to its excellent high temperature resistance, chemical resistance, and high mechanical strength. The gold plating treatment further enhances its conductivity, corrosion resistance, and aesthetics, making PI gold plating film an ideal choice for many high-tech products.

The thickness and model of PI gold-plated film are not fixed, but can be customized according to specific application scenarios. This flexibility isPI gold-plated filmThe application provides infinite possibilities. For example, in flexible display devices, thinner PI gold plating film can provide better flexibility and transparency; In circuit boards that require higher conductivity and stability, thicker gold plating layers may be chosen. Therefore, whether it is precise control from the micrometer to the nanometer level, or personalized customization for different needs, the thickness models of PI gold-plated films demonstrate their high flexibility and adaptability.

The thickness and type of PI gold-plated film not only determine its aesthetic appearance, but also profoundly affect its performance. Specifically, the thickness of the gold plating layer directly affects its conductivity, corrosion resistance, and reflective properties. A thicker gold plating layer can provide better conductivity and corrosion resistance, but it may also increase costs and reduce flexibility. Therefore, in practical applications, it is necessary to balance these performance parameters according to specific requirements.

For example, in the field of solar cells, appropriate thicknessPI gold-plated filmIt can significantly improve the reflectivity and collection efficiency of light, thereby enhancing the power generation efficiency of solar cells. In the aerospace field, more attention may be paid to the high temperature resistance, radiation resistance, and mechanical stability of gold plating films to ensure stable performance even in extreme environments.

The high-quality production of PI gold-plated film relies on advanced technological support and strict process control. During the production process, it is necessary to perform fine surface treatment and bottom coating on the PI film to enhance the adhesion between the metal layer and the substrate. At the same time, it is necessary to precisely control the gold plating process parameters, such as gold plating temperature, time, and coating thickness, to ensure the uniformity and adhesion of the gold plating layer.

In addition, advanced production equipment and testing methods are also key factors in ensuring the quality of PI gold plating film. By introducing automated production lines and precision testing equipment, full process monitoring and quality control of the production process can be achieved, ensuring that each batch of products meets established performance standards.

With the continuous advancement of technology and the expansion of applications,PI gold-plated filmIt is showing its broader application prospects. From flexible displays and solar cells to aerospace, biomedical and other fields, PI gold-plated film is gradually becoming the core material of many high-tech products due to its unique performance and customized advantages. In the future, we have reason to believe that with the joint efforts of researchers and engineers, PI gold-plated film will demonstrate its unique charm in more fields and contribute greater strength to technological progress and social development.

In summary, the thickness type of PI gold-plated film is one of the key factors affecting its performance and application fields. Through customized production and precise process control, we can adjust the thickness and performance parameters of the gold plating layer according to specific needs to meet the application requirements of different fields. This process not only reflects the perfect integration of technology and art, but also showcases humanity's relentless pursuit and innovative spirit in materials science.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2