Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

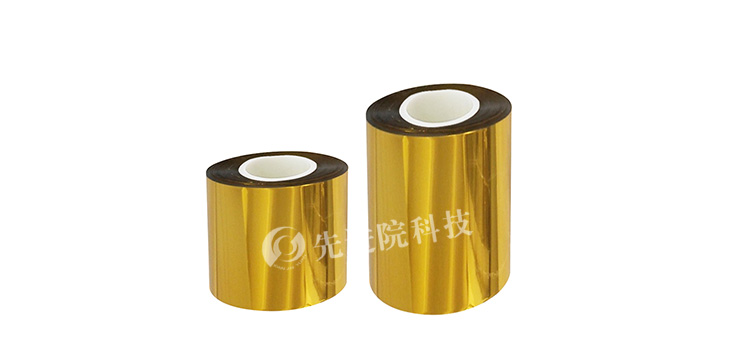

Polyimide (PI) gold plating film has a wide range of applications in microelectronics, optoelectronics, aerospace and other fields due to its excellent electrical properties and thermal stability. Vacuum coating technology is one of the key processes for preparing PI gold plating film, and its efficiency and cost directly affect the market competitiveness of the product. This article will explore how to improve vacuum coating technology by optimizing itPI gold-plated filmPay special attention to the technological progress and innovative practices of Advanced Institute (Shenzhen) Technology Co., Ltd. in the field of production efficiency and cost reduction.

Vacuum coating technology is a technique of depositing metal thin films on the surface of a substrate through physical or chemical methods in a high vacuum environment. For PI gold plating film, vacuum coating technology can not only provide a uniform and dense metal layer, but also maintain the physical and chemical properties of the PI substrate.

Improving the coating rate is the key to enhancing production efficiency. By optimizing the power and control parameters of the evaporation source, the metal evaporation rate per unit time can be increased, thereby improving the coating rate. Advanced Institute (Shenzhen) Technology Co., Ltd. has achieved a significant improvement in coating rate by precisely controlling the evaporation rate and substrate rotation speed.

The optimization of coating environment includes the control of vacuum degree and the adjustment of atmosphere. High vacuum degree can reduce the collision between gas molecules and evaporated metal atoms, and reduce the defects of thin films. Advanced Institute (Shenzhen) Technology Co., Ltd. adopts advanced vacuum system to ensure that the coating process is carried out under high vacuum degree, thereby improving the quality and uniformity of the film.

The surface condition of the substrate has a significant impact on the quality of the coating. By using pre-treatment methods such as chemical cleaning and plasma treatment, impurities and oxide layers on the surface of the substrate can be removed, improving the adhesion between the substrate and the metal layer.Advanced Institute (Shenzhen) Technology Co., LtdWe have multiple patented technologies in substrate pretreatment, effectively improving the adhesion and reliability of PI gold plating film.

Annealing treatment after coating can improve the crystallinity and density of the film, as well as enhance its electrical and thermal properties. Advanced Institute (Shenzhen) Technology Co., Ltd. adopts precise controlled annealing process to optimizePI gold-plated filmThe physical properties are improved while reducing energy consumption during the annealing process.

Automation and intelligence are important ways to reduce costs and improve efficiency. By introducing automated control systems and intelligent monitoring devices, precise control and real-time monitoring of the coating process can be achieved, reducing the impact of human factors on product quality. Advanced Institute (Shenzhen) Technology Co., Ltd. has implemented automation transformation on the production line, significantly improving production efficiency and product quality stability.

By optimizing vacuum coating technology, including increasing coating rate, optimizing coating environment, substrate pretreatment, coating post-treatment, and automation and intelligent transformation, significant improvements can be madePI gold-plated filmProduction efficiency and cost reduction. The technological innovation and practical experience of Advanced Institute (Shenzhen) Technology Co., Ltd. in these areas provide strong technical support for the large-scale production and application of PI gold plating film. With the continuous advancement and innovation of technology, the production cost of PI gold-plated film will be further reduced, and its market competitiveness will be enhanced.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2