Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

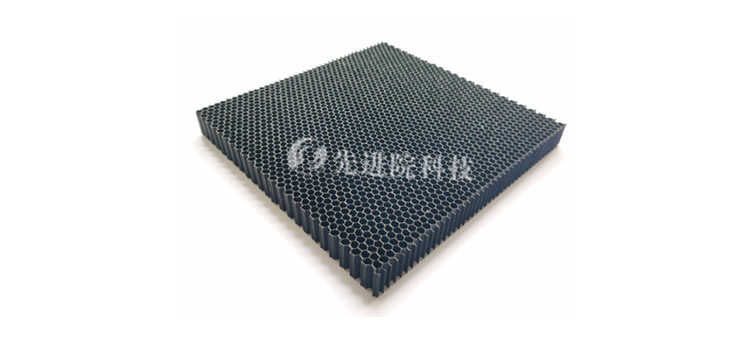

With the rapid development of modern electronic and communication technology, the demand for electromagnetic wave absorbing materials is increasing day by day. Honeycomb type absorbing materials have shown wide application prospects in multiple fields due to their unique structure and excellent absorbing performance. This article will explore the influence of different honeycomb structures on the electromagnetic wave absorption frequency range of honeycomb absorbing materials, and combine it with the research of Advanced Institute (Shenzhen) Technology Co., LtdResearch Platinum Brand Honeycomb Absorbing MaterialConduct a specific analysis.

The design inspiration for honeycomb type absorbing materials comes from the honeycomb structure in nature. By imitating this efficient and lightweight structural characteristic and combining it with specific absorbing materials, it achieves efficient absorption and dissipation of electromagnetic waves. Its uniqueness lies in its hexagonal structure resembling a honeycomb, which not only provides excellent mechanical properties and stability, but also enables the material to generate multiple reflections and scattering during electromagnetic wave propagation, thereby increasing the opportunities for interaction between electromagnetic waves and materials.

Honeycomb type absorbing materialThe absorption principle mainly includes:

The hexagonal aperture size and arrangement rule of the standard honeycomb structure enable the material to have good absorption effect over a wide frequency range. Taking 3-16 GHz as an example, the absorption performance of a certain sample meets the standard of less than -10 dB, and the maximum reflection loss is about -36 dB. The carbonyl iron particles (CI) prepared by vacuum bag technology and the epoxy resin composite material added with MWCNT, using glass fiber reinforced epoxy resin as the panel material and carbon fiber reinforced epoxy resin as the bottom plate material, have a bandwidth of less than -10 dB up to 18.37 GHz and a maximum reflection loss of about -46 dB.

By optimizing the design of the honeycomb structure, the absorption performance of the material can be further improved. The optimized honeycomb structure has a larger effective thickness for incident electromagnetic waves and a wider absorption bandwidth. In the same frequency band, the reflection loss can be significantly improved. For example, in the range of 5.8-18 GHz, the reflection loss is less than -10 dB, and the maximum reflection loss is about -29 dB. This optimization typically involves adjusting the aperture size, shape, and arrangement to achieve more efficient electromagnetic wave absorption.

In order to further enhance the absorbing performance of the material, the method of electroless nickel plating can also be used to improve the electromagnetic properties of glass fibers. This method does not require the addition of conductive particles or metal magnetic micro powders, and only enhances the material's absorption performance through nickel plated fibers. The results show that within the frequency range of 5.8~18 GHz, the reflection loss is less than -10 dB, and the maximum reflection loss is about -29 dB. This method not only simplifies the preparation process, but also improves the overall performance of the material.

Advanced Institute (Shenzhen) Technology Co., LtdAs a high-tech enterprise specializing in thermal conductive materials, shielding materials, and other fields, its platinum brand honeycomb absorbing materials have significant advantages in the market. This product not only has excellent mechanical load-bearing and absorbing properties, but also has the characteristics of lightweight and high strength, making it widely applicable in aerospace, mobile communication and other fields.

Specifically,Research Platinum Brand Honeycomb Absorbing MaterialBy adopting advanced preparation techniques and optimized structural design, effective absorption of electromagnetic waves can be achieved over a wide frequency range. For example, in the range of 3-18 GHz, the material has excellent absorption performance, with reflection losses all less than -10 dB, and the maximum reflection loss in some frequency bands can even reach -46 dB or more. This wideband characteristic enables the material to perform well in various application scenarios such as radar stealth and electromagnetic compatibility.

Honeycomb type absorbing materials have broad application prospects in multiple fields due to their unique structure and excellent absorbing performance. Different honeycomb structures have a significant impact on the frequency range of electromagnetic wave absorption of materials. By optimizing design and preparation processes, the absorption performance of materials can be further improved. Advanced Institute (Shenzhen) Technology Co., Ltd.'s platinum brand honeycomb absorbing material has become a leader in the market due to its excellent performance and wide application prospects. In the future, with the continuous emergence of new materials and technologies, the performance of honeycomb absorbing materials will be further improved, bringing more opportunities and challenges to the development of electronic and communication technologies.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2