Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

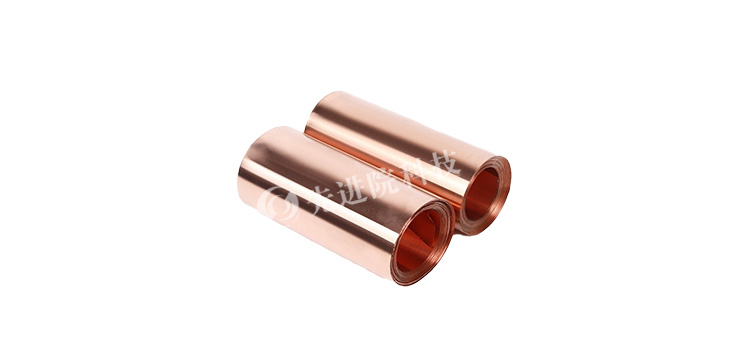

Polyimide (PI) copper plated film, as a composite material that combines high performance and multifunctionality, has shown broad application prospects in fields such as electronics, communication, aerospace, etc. Its conductivity is one of the important indicators for evaluating material properties, and copper layer thickness is a key factor affecting conductivity. Its research is of great significance for optimizing the performance and application of PI copper plating film. This article will explorePI copper plated filmThe relationship between conductivity and copper layer thickness, with special mention of the research achievements of Advanced Institute (Shenzhen) Technology Co., Ltd. in related fields.

PI copper plated film is a composite material formed by coating copper on the surface of polyimide film. Polyimide, as a high-performance polymer material, is renowned for its excellent heat resistance, corrosion resistance, good mechanical strength, and electrical insulation properties. When copper is combined with polyimide, this composite material not only inherits the above advantages of polyimide, but also has the high conductivity of copper, making it an ideal choice for high-performance electronic components.

The increase in copper layer thickness directly improvesPI copper plated filmThe conductivity of the material. A thicker copper layer means more conductive channels and lower resistance, thereby reducing energy loss during current transmission. This is particularly important for electronic components that require high conductivity, such as high-frequency circuits, flexible circuit boards, etc.

As the thickness of the copper layer increases, the conductivity of the PI copper plated film exhibits higher stability. During long-term use, a thicker copper layer can resist the erosion and mechanical stress of the external environment, maintaining stable conductivity. This is of great significance for improving the reliability and service life of electronic components.

The uniformity of copper layer thickness also has a significant impact on the conductivity of PI copper plated film. A uniform copper layer thickness can ensure that the current is evenly distributed on the surface of the material, avoiding local overheating and energy loss. Therefore, it is necessary to strictly control the thickness and uniformity of the copper layer during the preparation process to ensure the overall performance of the PI copper plated film.

In order to further investigate the relationship between the conductivity of PI copper plated film and the thickness of the copper layer, we conducted the following experiments:

Sample preparation: usingAdvanced Institute (Shenzhen) Technology Co., LtdThe PI film and copper plating solution provided were used to prepare PI copper plating film samples with different copper layer thicknesses through magnetron sputtering and electroplating processes.

Conductivity testing: Use a four point probe tester to measure the conductivity of each sample and record parameters such as resistivity and conductivity.

Data analysis: Compare the conductivity data of PI copper plated films with different copper layer thicknesses, and analyze the influence of copper layer thickness on conductivity.

The experimental results show that with the increase of copper layer thickness, the conductivity of PI copper plated film is significantly improved. When the thickness of the copper layer reaches a certain value, the conductivity tends to stabilize. In addition, the uniformity of copper layer thickness has a significant impact on conductivity, and a uniform copper layer thickness can significantly improve the uniformity of conductivity.

PI copper plated film has broad application prospects in flexible electronics, microelectronic packaging, new energy and other fields due to its unique performance advantages. With the in-depth study of the relationship between copper layer thickness and conductivity, we can further optimize the performance of PI copper plating film to meet the needs of different application scenarios. In the future, with the continuous advancement of preparation technology and further cost reduction, the market prospects of PI copper plated film will be even broader.

This study verified through experimentsPI copper plated filmThe relationship between conductivity and copper layer thickness was studied, and the mechanism of the influence of copper layer thickness on conductivity was analyzed in depth. The research results indicate that increasing the thickness of the copper layer can significantly improve the conductivity, stability, and uniformity of the PI copper plated film. This discovery provides important basis for optimizing the performance and application of PI copper plating film. In the future, we will continue to deepen research in related fields and promote the application and development of PI copper plating film in more fields.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2