Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

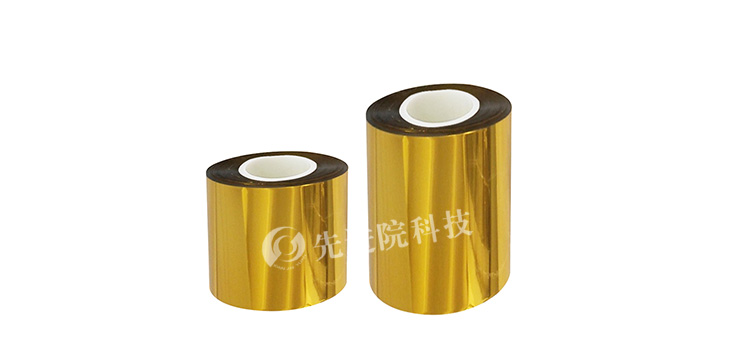

In ancient times, gold was revered as the supreme precious metal, representing wealth, power, and glory. Nowadays, people are more fond of and pursue the warm and glossy antique bronze color, and the copper gold plating process has become a popular technique. Let's uncover togetherGold-plated Beryllium CopperThe mysterious veil, exploring its production techniques and mysteries.

1、 Material preparation

Before carrying out the copper gold plating process, it is necessary to prepare sufficient copper sheets and gold foils. Copper sheets need to have a smooth and impurity free surface, while gold foil needs to be pure and golden, and then they should be placed separately in specific containers.

2、 Process steps

1. Pre treatment: Clean the copper sheet thoroughly and use a grinding tool to polish its surface to ensure a smooth finish. Then use paint remover to remove oil stains and attachments on the surface of the copper sheet.

2. Adhesive bonding: Soak the processed copper sheet in copper plating adhesive, and the adhesive solution adheres to the surface of the copper sheet to form a thin film for subsequent adhesion of the gold foil.

3. Gold plating: Place the soaked copper sheet into the gold foil groove, and the gold foil will adhere to the surface of the copper sheet. This process requires patience and skill to ensure that the gold foil is evenly covered on the copper sheet.

4. Knocking: After the gold foil is attached, carefully tap the surface of the gold foil with a small hammer to make it more tightly bonded with the copper sheet, eliminating bubbles and unevenness.

5. Setting: After the gold plating is completed, the made copper gold-plated crafts are sent to the oven for setting, heated to a certain temperature, so that the gold foil and copper sheet are tightly combined, making it more sturdy and durable.

3、 Polishing process

1. Polishing: After shapingCopper gold-plated craftsPolishing treatment is required, using a polishing machine or polishing solution to polish its surface to make it smoother and brighter.

2. Wax application: In order to further improve the glossiness of handicrafts, a layer of wax can be applied to their surface, which can be wiped and heated to make them more shiny.

4、 Quality inspection

Finally, strict quality inspection is required after the completion of handicraft production. Check the gold foil coverage, surface smoothness, and glossiness of the handicrafts to ensure that they meet the requirements.

Conclusion:Copper gold plating processAs an ancient and exquisite craft, it still plays an important role in the field of craftsmanship today. Through exquisite craftsmanship steps and meticulous processing, copper gold-plated crafts can showcase a quaint and elegant beauty, emitting a sparkling beauty. May we inherit and carry forward this precious craft tradition, allowing copper gold-plated crafts to continue shining brightly and bringing dazzling beauty to people.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2