Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

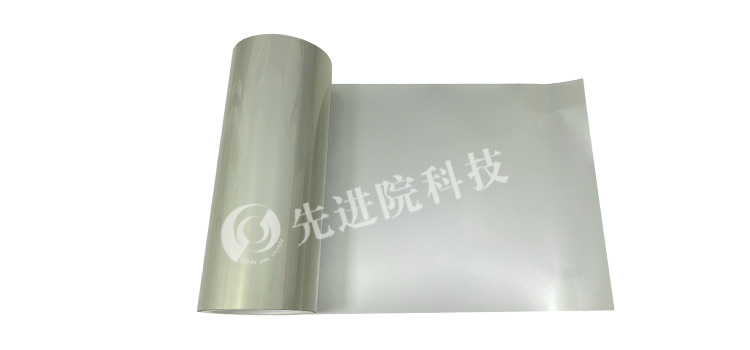

With the development of materials science, PP nickel plating film has attracted much attention due to its unique properties and wide application fields.PP nickel plating filmNot only does it have the advantages of lightweight and chemical corrosion resistance of PP substrate, but it also enhances its conductivity, wear resistance, and aesthetics through nickel plating treatment. However, the heat resistance of PP nickel plating film is a relatively complex issue, and its performance may be affected by various factors. This article will explore which situations can weaken the heat resistance of PP nickel plating film, and mention the research results of Advanced Institute (Shenzhen) Technology Co., Ltd. in related fields.

The basic heat-resistant temperature range of PP (polypropylene) materials is usually between 120 ° C and 150 ° C. However, the heat resistance of PP materials is not constant, but is influenced by their types and modification methods. For example, the nominal heat-resistant temperature of pure polypropylene in petrochemical plants can reach 110 ° C, but in actual use, it is often recommended to use it below 100 ° C. By adding specific modifiers such as glass fibers, mineral fillers, etc., the heat resistance of PP materials can be significantly improved. The heat resistance temperature of modified PP materials can usually reach 130 ° C to 142 ° C. Special reinforced PP materials such as glass fiber reinforced PP and mineral reinforced PP have even better heat resistance, with a temperature range of 158 ° C to 163 ° C.

The molecular chains of PP plastic are prone to breakage at high temperatures, leading to plastic deformation and degradation. High temperature can also accelerate the aging process of PP plastic, gradually reducing its mechanical properties. Therefore, the thermal stability of PP substrate is an important factor affecting the heat resistance of PP nickel plating film.

The nickel plating process itself has a certain impact on the heat resistance of PP film, but this impact is relatively small and mainly depends on the thickness and uniformity of the coating, as well as the bonding strength between the coating and the substrate. A thicker coating may improve the heat resistance of PP film to some extent, but an excessively thick coating may affect the flexibility and other physical properties of the film. The uniformity of the coating can ensure that the performance of various parts of the PP film remains consistent at high temperatures, avoiding local overheating or damage caused by uneven coating. The good bonding strength between the coating and PP substrate can ensure that the coating will not fall off or peel off in high temperature environments, thereby maintaining the overall stability of the film performance.

Post processing techniques such as roughening, activation, etcPP nickel plating filmThe heat resistance also has a certain impact. If the post-treatment process is improper, it may lead to a decrease in the adhesion between the coating and the substrate, thereby affecting the heat resistance of PP nickel plating film. For example, factors such as injection molding conditions, selection of injection machines, design of part shapes, and mold design can all lead to varying degrees of internal stress in different parts of the plastic part, resulting in the metallization layer being less resistant to collisions and a decrease in bonding strength.

In high temperature environments, if the PP nickel plating film is subjected to continuous pressure or external forces, its heat resistance may decrease. This is because the combined effect of high temperature and pressure can accelerate the aging process of PP substrate, leading to a decrease in the adhesion between the coating and the substrate, and may even cause the coating to peel off.

If there are corrosive gases or liquids in the environment, they may also be harmfulPP nickel plating filmThe heat resistance has adverse effects. Corrosive substances may corrode coatings or substrates, causing coating detachment or substrate performance degradation.

Advanced Institute (Shenzhen) Technology Co., Ltd. has a strong research foundation and rich application experience in the field of PP nickel plating film. The company is committed to improving the heat resistance of PP nickel plating films through optimizing nickel plating processes, improving post-treatment steps, and other means. At the same time, the company also focuses on the modification research of PP substrate, and further improves the heat resistance of PP nickel plating film by adding special modifiers and other methods. These research results not only provide a broader space for the application of PP nickel plating film, but also provide strong support for the development of related industries.

The heat resistance of PP nickel plating film is a relatively complex issue, and its performance may be affected by various factors such as the type and modification method of PP substrate, the quality of nickel plating process, the use environment, and post-treatment process. In practical applications, it is necessary to choose the appropriate PP nickel plating film material according to the specific usage environment and requirements, and follow the correct usage methods and maintenance measures to ensure its stable and reliable operation. At the same time, research institutions and enterprises should continuously strengthen research and technological innovation, promote the continuous improvement of the performance of PP nickel plating film and the continuous expansion of its application.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2