Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

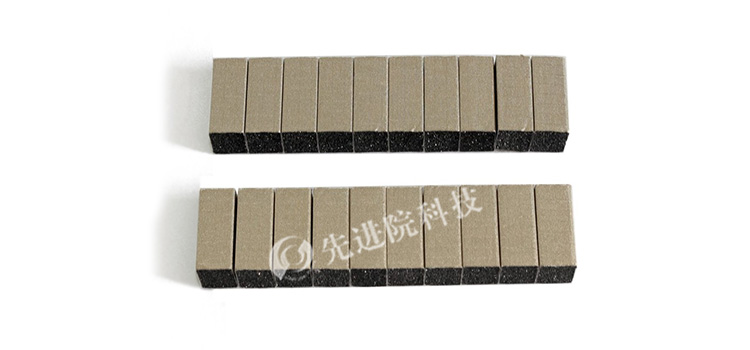

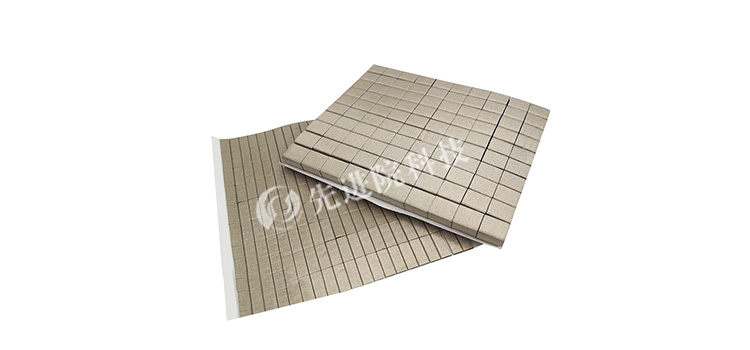

With the continuous development of electronic technology, surface mount technology (SMT) has been widely used in the electronic assembly industry. SMT foam, as an important component, its conductivity is crucial for the stable operation of electronic devices. However, after prolonged storage, the conductivity of SMT foam may significantly decrease, which is mainly influenced by multiple factors. This article will delve into the reasons for the decline in conductivity of SMT foam and combine it with the findings of Advanced Institute (Shenzhen) Technology Co., LtdYanbo brand SMT foamConduct a specific analysis.

The substrate of SMT foam is usually composed of flame-retardant sponge (such as polyurethane or EPDM). These materials may experience performance degradation due to aging after prolonged storage. The aging process can affect the support function of the substrate, thereby affecting the stability and conductivity of the conductive layer. For example, the research platinum brand SMT foam of Advanced Institute (Shenzhen) Technology Co., Ltd., although using high-quality substrates, may also experience performance degradation due to aging after long-term storage, thereby affecting its conductivity.

The conductive layer is the key to the conductivity of SMT foam, usually made of metals (such as copper, silver) or conductive polymers. After prolonged storage, the conductive layer may experience a decrease in conductivity due to oxidation, corrosion, or material degradation.Yanbo brand SMT foamAlthough the conductive layer has undergone special treatment, it may still be affected by environmental factors and experience performance degradation after prolonged storage.

The cell structure of SMT foam may change during prolonged storage, such as cell collapse or deformation. These changes will affect the formation and conductivity of the conductive network, leading to a decrease in conductivity. The uneven distribution of pores may also lead to unstable conductivity. The pore structure of SMT foam from Yanbo brand may also change after prolonged storage, thereby affecting its conductivity.

During the preparation process of foam, the orientation of conductive fillers can affect their electrical conductivity. After prolonged storage, the orientation of the conductive filler may change, leading to a decrease in conductivity. The orientation of conductive fillers is strictly controlled during the preparation process of Yanbo brand SMT foam, but attention should still be paid to the possible orientation changes that may occur after prolonged storage.

The cutting process may damage the conductive layer or alter its structure, thereby affecting its conductivity. If the cutting process is improper or not properly handled after cutting, these damages may worsen after prolonged storage, leading to further deterioration of conductivity.Yanbo brand SMT foamAdvanced processes and techniques are used during the cutting process to ensure the integrity of the conductive layer, but attention should still be paid to potential damage after prolonged storage.

The change in temperature will affect the resistivity of conductive materials, thereby affecting the conductivity of SMT foam. The conductivity of SMT foam may change after prolonged storage in high or low temperature environments. Although SMT foam has relatively low humidity requirements for the environment, its conductivity may still change under extreme humidity conditions. Excessive or insufficient humidity can lead to a decrease in conductivity. In the design and production process of Yanbo brand SMT foam, the influence of environmental factors on its conductivity has been fully considered. However, it is still necessary to pay attention to the possible environmental impacts after long-term storage.

The surface treatment of SMT foam (such as electroplating, spraying, etc.) can change its surface conductivity and adhesion. After prolonged storage, these surface treatments may lead to a decrease in conductivity due to aging, corrosion, or wear. Yanbo brand SMT foam adopts advanced technology and materials in surface treatment to ensure its long-term stability, but attention should still be paid to its possible aging phenomenon after long-term storage.

If SMT foam is affected by adverse factors such as direct sunlight, humidity, and chemical corrosion during storage, its conductivity may also decrease. During the storage process of Yanbo brand SMT foam, it is necessary to strictly follow the prescribed conditions to avoid a decrease in conductivity caused by improper storage conditions.

in summary,SMT foamThe main reasons for the decrease in conductivity after long-term storage include substrate aging, degradation of conductive layer, changes in pore structure, changes in the orientation of conductive fillers, damage during cutting, environmental factors, and surface treatment aging. In order to maintain the stable conductivity of SMT foam, it is necessary to fully consider these factors in the design, production, storage, and use processes, and take effective measures for prevention and control. The research platinum brand SMT foam of Advanced Institute (Shenzhen) Technology Co., Ltd., as a high-quality product in the industry, still needs to be monitored for changes in its conductivity after long-term storage, and appropriate maintenance and management measures should be taken.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2