Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Polyethylene terephthalate (PET) film has shown great potential in many application fields due to its excellent optical properties, good insulation, and stable chemical properties. In recent years, with the maturity and development of copper plating technology, PET copper plated film has become a bridge connecting traditional materials with emerging applications.

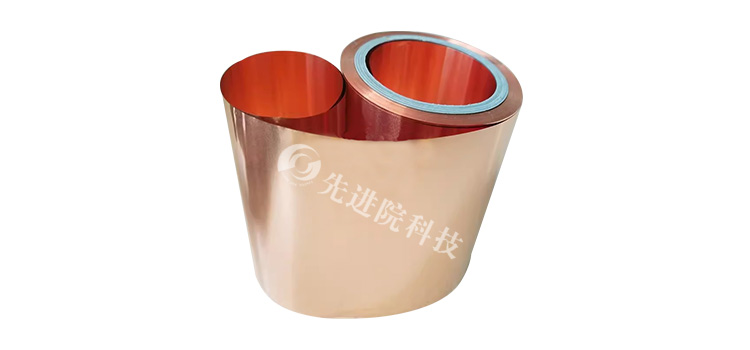

PET copper plated filmIt is a composite material formed by uniformly depositing a copper layer on the surface of PET film through advanced coating technology. This material combines the inherent advantages of PET film with the excellent conductivity of metal coating, and is widely used in fields such as flexible circuit boards, electromagnetic shielding, sensors, etc.

Wide thickness range: available from4.5 μ m to 188 μ mThe thickness model can be customized according to the specific needs of customers to ensure that it meets the requirements of diverse application scenarios.

Uniform coating: Adopting advanced coating technology produced by the institute, the copper layer is evenly distributed, effectively improving the overall performance of the product.

High conductivity: PET film treated with precision copper plating has excellent conductivity, which can effectively reduce losses during signal transmission.

Processing flexibility: PET copper plated film has good processing performance, easy to cut, bend and other processing operations, suitable for manufacturing needs of various complex shapes.

Environmentally friendly: While ensuring material performance, we strictly follow international environmental standards to ensure the sustainability of our products.

Flexible Circuit Board (FPC): PET copper plated film has become an ideal material for FPC manufacturing due to its good flexibility and conductivity, and is suitable for portable electronic devices such as smartphones and tablets.

Electromagnetic shielding: In electronic devices, it is used to reduce external electromagnetic interference and protect internal circuits from damage.

Sensors: With their stable chemical properties and good electrical performance, they are widely used in the manufacturing of various types of sensors, such as temperature and pressure sensors.

Other high-end applications: such as LED displays, solar panels, and other fields,PET copper plated filmIt is gradually expanding its application boundaries.

We are well aware that every project has its unique requirements. Therefore, in addition to providing standard specifications of products, we have also launched personalized customization services to ensure that customers can obtain the most suitable solution for their own projects. Our professional team will spare no effort to explore the best solution with you, whether it is specific size requirements or special performance indicators.

Advanced production line: adopting modern production equipment to ensure efficient and stable production process.

Strict quality control: From raw material procurement to finished product delivery, every step undergoes rigorous quality testing to ensure product consistency and reliability.

Flexible production capacity: With strong production capabilities, it can quickly respond to changes in market demand and ensure timely delivery.

conclusion

With the continuous advancement of technology,PET copper plated filmThe application prospects will be even broader. We are committed to continuous innovation and providing customers with higher quality products and services. If you are looking for a material solution that can maintain the original characteristics of PET film while achieving efficient conductivity, then PET copper plated film is undoubtedly your ideal choice. Let's work together to create a better future!

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2