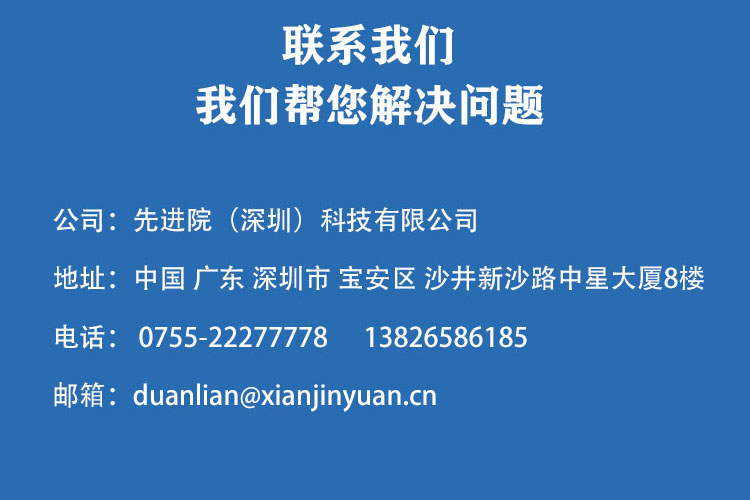

Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

High temperature co fired AlN multilayer wiring substrateFill hole tungsten paste, is a special metal paste used to fill holes on wiring substrates in high-temperature co fired ceramic processes to achieve circuit connections and thermal conductivity. The preparation and application of this tungsten paste are crucial for improving the performance of multi-layer wiring substrates.

The filling tungsten paste for high-temperature co fired AlN multilayer wiring substrates is usually composed of a mixture of tungsten powder, inorganic binder, and organic carrier mixed in a certain proportion. Among them, tungsten powder mixture is the main conductive component, and its particle size distribution and purity have a significant impact on the properties of tungsten paste. Inorganic binders are used to enhance the adhesion between tungsten powder and ceramic substrates, while organic carriers are used to regulate the fluidity and stability of tungsten slurry.

During the preparation process, the tungsten powder mixture, inorganic binder, and organic carrier are first mixed according to a predetermined mass ratio to form a uniform tungsten slurry. Then, tungsten paste is filled into the holes on the wiring substrate through methods such as screen printing or glue dispensing. After filling, drying and high-temperature sintering are carried out to tightly bond the tungsten paste with the ceramic substrate, forming a stable circuit connection.

1. High thermal conductivity: AlN ceramics have high thermal conductivity, and filling tungsten paste as a circuit connection material also requires good thermal conductivity to ensure the stability and reliability of the circuit in high temperature environments.

2. Good adhesion: The filling tungsten paste needs to be tightly bonded to the ceramic substrate to ensure the stability and reliability of the circuit connection. Inorganic binders play a crucial role in the preparation process, enhancing the adhesion between tungsten powder and ceramic substrates.

3. Excellent welding performance: Due to the high melting point of tungsten (3400 ℃), direct welding may be difficult. Therefore,Fill hole tungsten pasteUsually, nickel palladium and other metals need to be plated on the surface to increase its welding ability and facilitate subsequent assembly and connection.

4. Good flowability: During the preparation process, the filling tungsten paste needs to have good flowability in order to smoothly fill the holes on the wiring substrate. Organic carriers play an important role in regulating the fluidity of tungsten paste.

High temperature co fired AlN multilayer wiring substrateFill hole tungsten pasteIt has a wide range of applications in fields such as electronic packaging, power electronics, and optical communication. Especially in the packaging of high-density, high-power multi chip modules (MCMs), AlN multilayer wiring substrates have become the preferred substrate and packaging materials due to their excellent properties such as high thermal conductivity and low dielectric constant. As one of the key materials, filling tungsten paste is of great significance for improving the performance and reliability of MCM.

In summary, the filling tungsten paste for high-temperature co fired AlN multilayer wiring substrates is an important electronic packaging material, and its preparation method and performance characteristics are crucial for improving the performance of multilayer wiring substrates. With the continuous development and progress of the electronics industry, the application fields of tungsten paste for filling holes will become more extensive, and the market demand will continue to grow.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2