Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

The silver plating technology for plastic film has attracted much attention due to its wide applications in various fields such as electronics, optics, and packaging.Advanced Institute (Shenzhen) Technology Co., LtdThis article reviews the silver plating techniques of four commonly used plastic films, namely polyimide (PI), polyethylene terephthalate (PET), polypropylene (PP), and polyethylene naphthalate (PEN), and discusses in detail the properties of their silver plated films. The influence of different substrates on the silver plating layer was compared and analyzed through experimental data, providing a reference for selecting suitable materials and optimizing silver plating processes.

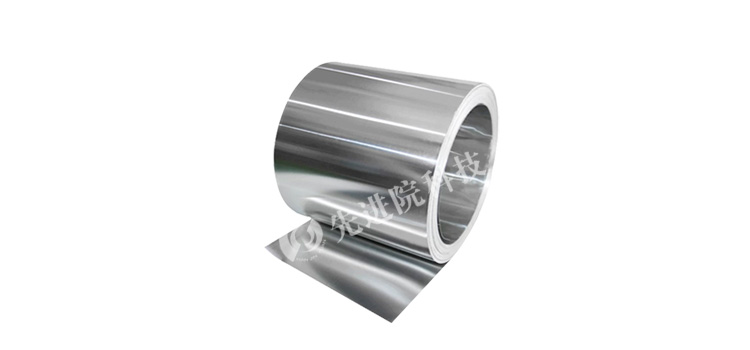

Plastic film plays an important role in modern industry due to its excellent properties such as lightweight, flexibility, and chemical resistance. However, in order to endow plastic films with better conductivity, reflectivity, and shielding effectiveness, silver plating technology has become one of the effective means to improve film performance.

Silver plating techniques typically include various methods such as physical vapor deposition (PVD), chemical silver plating (ECD), and electroplating silver plating (ED). This article focuses on two common and practical techniques, chemical silver plating and electroplating silver plating.

Chemical silver plating is the process of reducing silver ions to silver atoms through chemical reduction reactions, and depositing them on the surface of plastic films to form a layer of silver film. This method does not require an external power source and is easy to operate, but the uniformity and thickness control of the coating are relatively difficult.

Silver electroplating uses electrolysis to reduce silver ions to silver atoms on the cathode under the action of direct current, depositing them on the surface of plastic film to form a coating. The advantages of silver electroplating are good coating quality and controllable thickness, but it requires complex equipment and high process conditions.

Polyimide (PI) films exhibit excellent thermal and chemical stability in high-temperature environments. The silver plating process of PI film usually adopts silver electroplating technology to ensure the uniformity and adhesion of the coating.

PET film is a low-cost and high-performance material widely used in the fields of packaging and electronics. The silver plating process of PET film usually uses chemical silver plating to adapt to its lower thermal stability.

Polypropylene (PP) film has good chemical resistance and mechanical strength, but its surface activity is low and it is not easy to directly silver plate. Therefore, surface modification treatment (such as plasma treatment or chemical activation) is usually required before silver plating.

PEN film combines the processing performance of PET with the heat resistance of PI, making it an ideal silver plated substrate. The silver plating process of PEN film can be either chemical silver plating or electroplating silver plating, depending on the required coating characteristics and application requirements.

To verify the differencesPlastic film silver plated filmThe following experiments were conducted on the performance of:

Through the silver plating process and performance analysis of four types of plastic films, PI, PET, PP, and PEN, the following conclusions can be drawn:

Future research directions should focus on further optimizing silver plating processes, improving the uniformity and adhesion of coatings, and developing new plastic substrates to meet more diverse needs. Advanced Institute (Shenzhen) Technology Co., Ltd. will continue to be committed to technological innovation, provide more high-quality products and services to the market, and promote the continuous progress of silver plating technology for plastic films.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2