Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

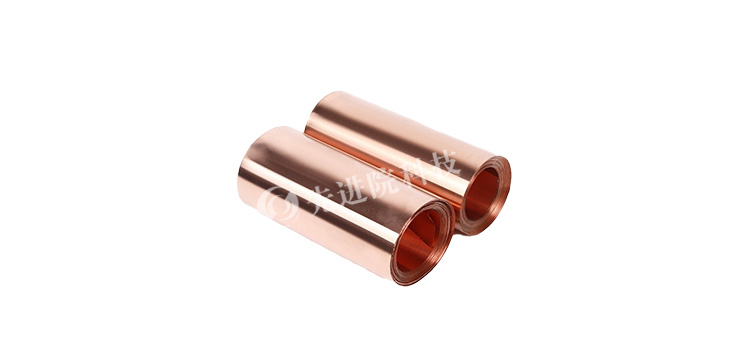

In the field of modern electronic materials science, PEN (Polyethylene Naphthalate) copper plated film has become an important material in flexible displays, energy storage films, and medical electronic products due to its high strength, high rigidity, high temperature resistance, and good electrical insulation performance. This article will explorePEN copper plated filmHow is the dielectric constant affected by the copper layer, and mention the research progress of Advanced Institute (Shenzhen) Technology Co., Ltd. in this field.

The PEN film itself has excellent physical and chemical properties, which enable the PEN copper plated film to withstand certain external impacts and environmental stresses during long-term use during the preparation process, thereby maintaining the stability of its performance. In flexible display screens, PEN copper plated film is a key material for signal transmission and circuit connection, and its conductivity is particularly critical.

The dielectric constant (ε) is a measure of a material's ability to store charges in an electric field, and for electronic materials, this parameter is crucial.PEN copper plated filmThe dielectric constant of copper is influenced by various factors, among which the thickness, uniformity, and purity of the copper layer are key factors.

Copper layer thickness:

A thicker copper plating layer can provide better conductive channels, but an excessively thick copper layer may lead to a decrease in the bonding force between the coating and the substrate, which in turn affects the conductivity and dielectric constant. Therefore, it is necessary to strictly control the thickness of the copper plating layer during the preparation process to achieve optimal dielectric performance.

Uniformity of copper layer:

The uniformity of the copper plating layer directly affects the uniformity of the dielectric constant. Uneven copper plating can lead to a decrease in local conductivity and even cause circuit failures, thereby affecting the overall dielectric performance. Therefore, appropriate measures need to be taken during the electroplating process to ensure the uniformity of the copper plating layer.

Copper layer purity:

High purity copper coating can reduce the influence of impurities on conductivity and dielectric constant. Impurities may cause uneven distribution of charges in the material, thereby affecting the dielectric constant. Therefore, when preparing PEN copper plated film, it is necessary to choose high-purity copper material as the coating material.

Advanced Institute (Shenzhen) Technology Co., Ltd. has conducted in-depth research in the field of PEN copper plating film, committed to improving the dielectric and conductive properties of materials. The company optimizes the electroplating process and strictly controls the thickness, uniformity, and purity of the copper layer to achieve the optimal dielectric constant.

In addition,Advanced Institute (Shenzhen) Technology Co., LtdSignificant progress has also been made in material modification. By introducing advanced molecular design technology, the company has successfully improved the high-temperature stability and dielectric properties of PEN films, providing more reliable material solutions for fields such as flexible displays, energy storage membranes, and medical electronic products.

With the rapid growth of OLED screen substrates, energy storage films, and medical electronic product markets, the demand for PEN copper plated films is also constantly increasing. According to industry reports, the global market value of PEN film will continue to grow in the coming years. Advanced Institute (Shenzhen) Technology Co., Ltd., with its outstanding research and development capabilities and product quality, is actively seizing this market and leading the industry's technological upgrading.

Especially in the field of flexible display screens,PEN copper plated filmAs a key material for signal transmission and circuit connection, the optimization of its dielectric constant and conductivity will directly affect the performance and reliability of the display screen. Therefore, Advanced Institute (Shenzhen) Technology Co., Ltd. will continue to increase its research and development efforts to promote continuous innovation and application expansion of PEN copper plating film technology.

The dielectric constant of PEN copper plated film is influenced by various factors such as copper layer thickness, uniformity, and purity. By optimizing the electroplating process and material modification technology, Advanced Institute (Shenzhen) Technology Co., Ltd. has successfully improved the dielectric and conductive properties of PEN copper plated films, making important contributions to the development of electronic materials science. In the future, with the continuous advancement of technology and the sustained growth of market demand, PEN copper plating film will demonstrate its unique advantages and application value in more fields.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2