1、 The Importance and Application Fields of Silver Plated Conductive Cloth

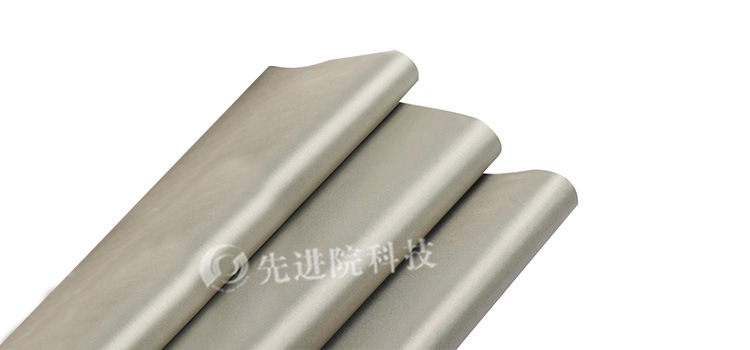

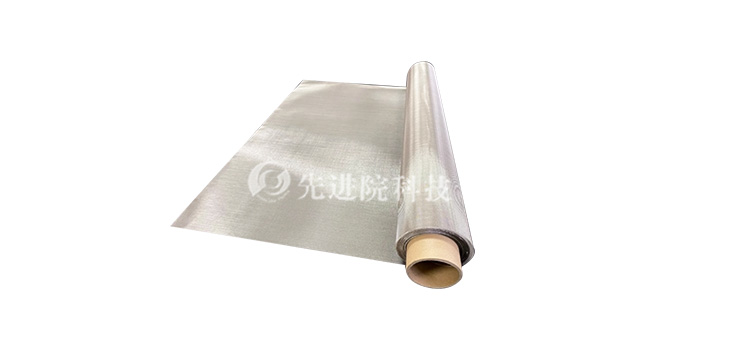

Silver plated conductive cloth is widely used in many fields due to its excellent conductivity, electromagnetic shielding effectiveness, and flexibility. Advanced Institute (Shenzhen) Technology Co., LtdResearch Platinum Brand Silver Plated Conductive ClothIt stands out in the market with its high quality and stability.

In the field of electronic devices, silver plated conductive cloth can be used for electromagnetic shielding of devices such as mobile phones, computers, and tablets, reducing the impact of electromagnetic interference on device performance. In the aerospace field, its lightweight and high conductivity properties help reduce the weight of aircraft while ensuring the stable operation of electronic systems. In medical equipment, silver plated conductive cloth can be used for electrophysiological monitoring electrodes and other parts to ensure the accuracy and stability of signal transmission.

2、 Factors affecting surface resistivity

-

Silver plating thickness: Generally speaking, the thicker the silver plating thickness, the lower the surface resistivity. Experimental data shows that when the thickness of the silver plating layer increases from 1 μ m to 3 μ m, the surface resistivity can decrease from 0.05 Ω/sq to 0.02 Ω/sq. However, an increase in the thickness of the silver plating layer will also lead to an increase in cost and increased process difficulty.

-

Base fabric material: Different base fabric materials also have an impact on surface resistivity. For example, using polyester fiber base fabric

Silver plated conductive clothCompared with nylon fabric, the surface resistivity of polyester fiber fabric may be lower under the same silver plating process. This is because polyester fibers have good flatness and low surface roughness, which is conducive to the uniform adhesion of silver plating layers.

-

Silver plating process parameters: Temperature, current density, plating solution composition, and other parameters in the silver plating process can all affect the surface resistivity of silver plated conductive cloth. Taking current density as an example, when the current density increases from 1A/dm ² to 3A/dm ², the surface resistivity may decrease from 0.03 Ω/sq to 0.015 Ω/sq. However, excessive current density may lead to rough crystallization of the silver plating layer, affecting its performance.

3、 The technological advantages of Advanced Institute (Shenzhen) Technology Co., Ltd

Advanced Institute (Shenzhen) Technology Co., Ltd. adopts advanced processes and technologies in the production process of silver plated conductive cloth to ensure that the surface resistivity of the product can meet various specific application requirements.

-

Accurate silver plating thickness control: Through advanced electroplating equipment and process monitoring systems, the company can precisely control the thickness of the silver plating layer, ensuring that the surface resistivity meets the requirements while minimizing costs. For example, for a specific electromagnetic shielding application of electronic devices, the company can control the thickness of the silver plating layer at 2 μ m ± 0.2 μ m to stabilize the surface resistivity at around 0.03 Ω/sq.

-

High quality fabric selection:

Research Platinum Brand Silver Plated Conductive ClothHigh quality base fabric materials are selected and subjected to strict pre-treatment processes to ensure that the flatness and surface roughness of the base fabric meet the requirements. At the same time, the company will also choose different materials of base fabric according to different application needs to achieve the best balance between performance and cost.

-

Optimized silver plating process parameters: The company's R&D team has determined the optimal silver plating process parameters through extensive experimentation and optimization. For example, fine adjustments are made in temperature, current density, plating solution composition, etc. to ensure that the surface resistivity of silver plated conductive cloth remains stable within a specific range. At the same time, the company also adopts advanced post-processing techniques such as passivation and anti discoloration treatment to improve the oxidation resistance and stability of the silver plating layer.

4、 Practical application case analysis

-

Electromagnetic shielding of electronic devices: In the electromagnetic shielding application of a high-end mobile phone,

Advanced Institute (Shenzhen) Technology Co., LtdThe research platinum brand silver plated conductive cloth was selected. By precisely controlling the surface resistivity to around 0.02 Ω/sq, the electromagnetic interference inside the phone is effectively shielded, improving the signal reception and transmission quality of the phone. Meanwhile, due to the flexibility and lightweight characteristics of silver plated conductive cloth, it also provides greater flexibility for the design of mobile phones.

-

Medical equipment electrophysiological monitoring electrodes: In medical equipment electrophysiological monitoring electrodes, the stability of surface resistivity is crucial for the accuracy of signal transmission. The silver plated conductive cloth of Advanced Institute (Shenzhen) Technology Co., Ltd. has strict quality control to keep the surface resistivity at an extremely low level, ensuring good contact and signal transmission between the electrode and human skin. In practical applications, the conductive cloth can accurately monitor the electrophysiological signals of the human body, providing reliable basis for doctors' diagnosis.

5、 Conclusion

Silver plated conductive clothThe control of surface resistivity is key to meeting specific application requirements. The research platinum brand silver plated conductive cloth under Advanced Institute (Shenzhen) Technology Co., Ltd., with its advanced technology and strict quality control, can provide high-quality conductive materials for customers in different fields. By precisely controlling the thickness of the silver plating layer, selecting high-quality base fabrics, and optimizing silver plating process parameters, the company is able to meet the strict requirements for surface resistivity in various complex application scenarios, contributing to the development of electronic technology.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.