Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

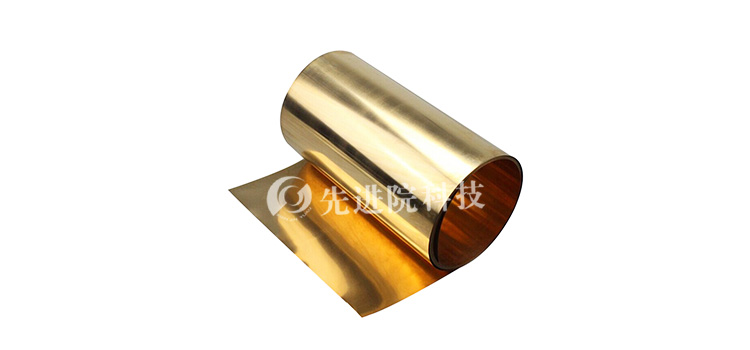

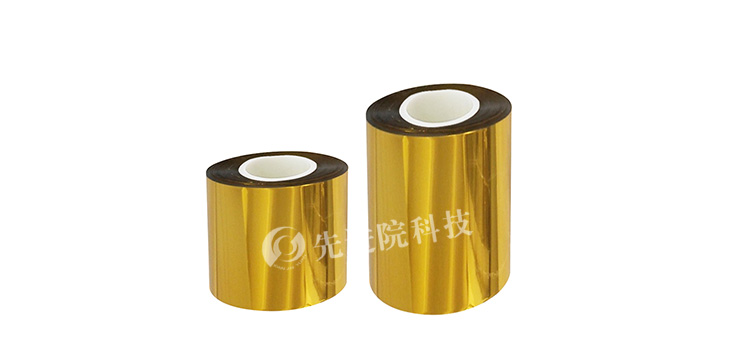

Gold-plated Beryllium CopperAs a traditional craft, it is still widely used in today's design field. Its unique metallic texture and luster make copper plated products have a unique charm in decoration, furniture, handicrafts, and other aspects. When making copper gold-plated products, the process flow is crucial, only rigorous process flow can ensure the quality and beauty of the products. We will provide a detailed introduction to the process of copper gold plating from the aspects of preparation work, surface treatment, copper coating, gold foil plating, and polishing.

Preparation work: The first step in the copper gold plating process is the preparation work. Firstly, high-quality copper products need to be selected to ensure a smooth surface, free from oxidation and stains. Secondly, prepare the necessary tools and raw materials, including gold foil, copper coating, polishing tools, etc. The quality of preparation work is crucial for the subsequent process, and only by doing a good job of preparation can we ensure the smooth progress of the subsequent process.

Surface treatment: Before copper gold plating, copper products need to be surface treated to ensure copper coating andGold foil platingThe adhesion and flatness. The methods of surface treatment include polishing, acid washing, degreasing, and applying primer. Through surface treatment, the surface of copper products can be made smoother and smoother, which is beneficial for subsequent coating and plating processes.

Copper coating: One of the core steps in copper gold plating is copper coating. Copper coating can be carried out by spraying, dipping or brushing. Through copper coating, the entire product can present a copper like texture and color, increasing its metallic feel and texture. When conducting copper coating, it is necessary to control the thickness and uniformity of the coating to ensure the consistency of the entire product surface.

Gold foil plating: Gold foil plating is one of the key steps in the copper gold plating process. Gold foil is a very thin metal sheet that can be coated on the surface of copper products through specialized processing techniques, giving them a golden texture and luster. Gold foil plating requires professional technology and equipment. Through appropriate temperature and pressure control, gold foil can be perfectly plated on the surface of copper products, increasing their sense of luxury and sophistication.

Polishing: The final step is polishing. Polishing is a key step in making the surface of copper gold-plated products smoother and more delicate. Through polishing, the surface of copper products can be made brighter, increasing their visual effect and hand feel. When polishing, it is necessary to choose appropriate polishing tools and methods, control the polishing force and time, and ensure that the surface of copper gold-plated products is smooth and flat.

Summary:

The complexity and precision of the copper gold plating process determine the quality and value of the product. The perfect combination of traditional craftsmanship and modern technology makes copper gold-plated products still highly favored in today's market. Through rigorous preparation, meticulous processing, exquisite copper coating, and preciseGold foil platingWith meticulous polishing, copper gold-plated products with soft texture and bright luster can be produced, showcasing unique artistic charm and craftsmanship taste. I hope this article is helpful for everyone to understand the copper gold plating process. Please continue to follow us for more articles.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2