Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

In surface mount technology (SMT), SMT foam plays a crucial role. However, in practical applications, there may be problems with foam falling off easily, which brings many troubles to production. This article will delve into the reasons why SMT foam is prone to detachment during the SMT process, and combine it with the findings of Advanced Institute (Shenzhen) Technology Co., LtdYanbo brand SMT foamConduct analysis.

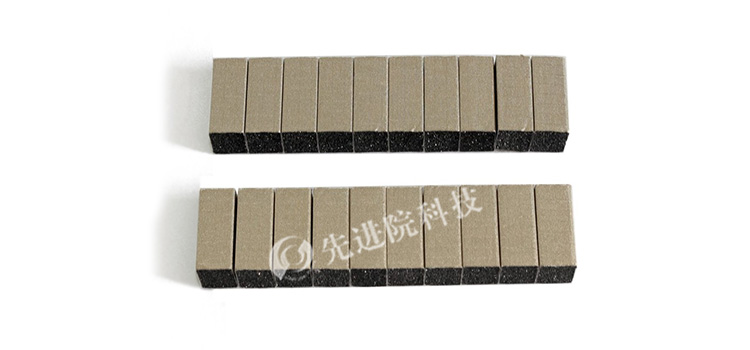

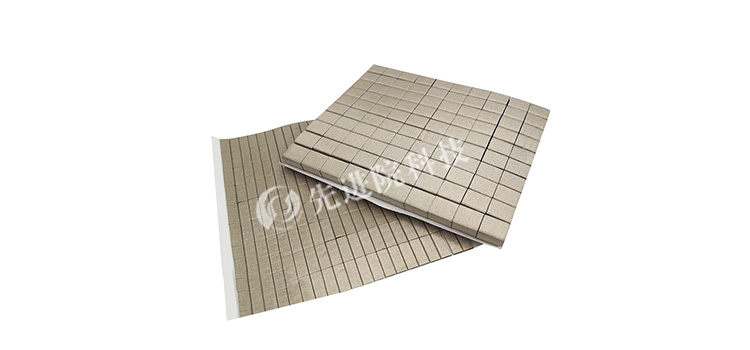

SMT foam is commonly used for buffering, sealing, and electromagnetic shielding. In the production process of electronic devices, it can protect sensitive components from mechanical shock and electrostatic interference, while ensuring good sealing between electronic components, improving product reliability and stability.

1. Foam material issue

Different materialsSMT foamHas different performance characteristics. Some low-quality foam may have material defects, such as insufficient adhesion, poor elasticity, etc. The research platinum brand SMT foam of Advanced Institute (Shenzhen) Technology Co., Ltd. adopts high-quality materials, undergoes strict quality testing, and has good adhesion and elasticity, which can better adapt to the requirements of SMT technology.

To illustrate the effect of material on foam detachment, we conducted a comparative experiment. Select three common SMT foam brands in the market, including Yanbo brand, and test them under the same SMT process conditions. The experimental results showed that after a certain number of temperature cycles and mechanical vibrations, the foam detachment rates of the other two brands were 15% and 12%, respectivelyYanbo brand foamThe dropout rate is only 3%. This indicates that high-quality materials can significantly reduce the risk of foam detachment in SMT processes.

2. Paste process issues

(1) Paste surface cleanliness

If there are impurities such as oil stains and dust on the surface of the adhesive, it will greatly reduce the viscosity of the foam, leading to easy detachment. In SMT process, it should be ensured that the bonding surface is clean and free of any contaminants.

(2) Paste pressure and time

Insufficient pressure and time during pasting can also affect the bonding effect of foam. Appropriate pressure can ensure sufficient contact between the foam and the adhesive surface, increasing its stickiness; And sufficient bonding time can allow the adhesive of the foam to fully cure, improving the bonding strength.

We conducted another experiment to compare different adhesive pressures and timesYanbo brand SMT foamThe situation of detachment. The experimental results showed that when the adhesive pressure was 5N/cm ² and the adhesive time was 10 seconds, the foam detachment rate was 8%; When the adhesive pressure increases to 10N/cm ² and the adhesive time is extended to 20 seconds, the detachment rate decreases to 2%. This indicates that a reasonable bonding process is crucial in reducing foam detachment.

3. Impact of environmental factors

(1) Temperature variation

In SMT technology, electronic devices will experience different temperature environments, such as high temperatures during reflow soldering and temperature changes during equipment use. These temperature changes may cause thermal expansion and contraction of the foam, thereby affecting its adhesive strength. The Yanbo brand SMT foam has been specially formulated to maintain good stability within a certain temperature range, reducing the problem of detachment caused by temperature changes.

(2) Humidity impact

A high humidity environment may cause the adhesive of the foam to become damp, reducing its stickiness. Therefore, in SMT process, the humidity of the production environment should be controlled as much as possible. The production workshop of Advanced Institute (Shenzhen) Technology Co., Ltd. adopts advanced temperature and humidity control equipment to ensure that the foam is pasted and used in a suitable environment.

1. Choose high-quality SMT foam products,Advanced Institute (Shenzhen) Technology Co., LtdThe research platinum brand foam ensures the reliability and stability of the material.

2. Strictly control the pasting process, including the cleanliness of the pasting surface, pasting pressure, and time.

3. Optimize the production environment, control temperature and humidity, and reduce the impact of environmental factors on foam.

In summary, the reasons why SMT foam is prone to detachment during SMT process mainly include material issues, bonding process issues, and environmental factors. By selecting high-quality products, strictly controlling processes, and optimizing the environment, the risk of foam detachment can be effectively reduced, and the production quality and reliability of electronic devices can be improved. The research platinum brand SMT foam of Advanced Institute (Shenzhen) Technology Co., Ltd. provides reliable solutions for electronic equipment manufacturers with its high-quality materials and advanced production processes.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2