Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

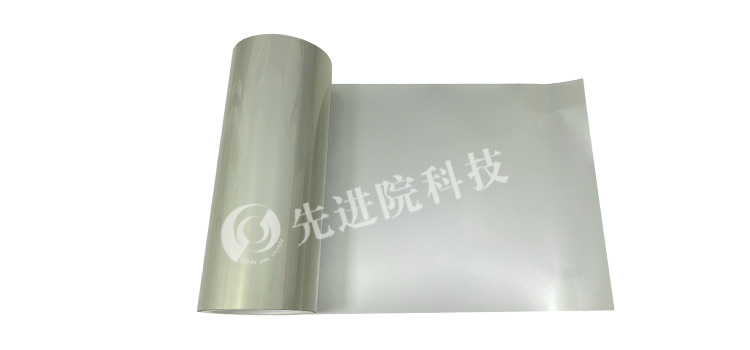

With the rapid development of technology, PI (polyimide) films have been widely used in fields such as electronics, aviation, and aerospace due to their excellent high and low temperature resistance, electrical insulation, adhesion, radiation resistance, and dielectric resistance. In order to further enhance the performance of PI thin films, many researchers and manufacturers choose to coat their surfaces with a layer of nickel (Ni). Nickel plating not only enhances the conductivity of PI films, but also endows them with certain electromagnetic shielding effectiveness. However, the performance of nickel plated PI films under extreme temperature conditions has become a topic that requires further research. This article will provide a detailed introduction on how to evaluateNickel plating on PI filmThe high and low temperature resistance performance of the later stage, and special mention of the contribution of Advanced Institute (Shenzhen) Technology Co., Ltd. in this field.

After nickel plating on PI film, its high and low temperature resistance directly affects its application effect in extreme temperature environments. At high temperatures, the nickel plating layer may soften, grain grow, oxidize or become brittle, leading to a decrease in the performance, detachment or failure of the plating layer. In low-temperature environments, the nickel plating layer may become brittle and crack, which can also lead to a decrease in performance. Therefore, evaluating the high and low temperature resistance of PI thin films after nickel plating is crucial to ensure their stability and reliability in practical applications.

The high and low temperature test chamber is used for evaluationNickel plating on PI filmThe main tool for high and low temperature resistance performance. The testing steps include sample preparation, test chamber setup, sample placement, running tests, result observation, and analysis. The specific process is as follows:

In addition to testing in high and low temperature test chambers, scanning electron microscopy, microscopy, tensile testing, and other methods can also be used to assist in evaluationPI nickel plating filmHigh and low temperature resistance performance. These methods can provide a deeper understanding of the microstructure and mechanical properties changes of nickel plating under extreme temperature conditions.

Advanced Institute (Shenzhen) Technology Co., Ltd. has conducted in-depth research in the field of PI nickel plating film and achieved significant results. The company not only has advanced production equipment and testing methods, but also has an experienced and skilled R&D team. In evaluating the high and low temperature resistance of PI film after nickel plating,Advanced Institute (Shenzhen) Technology Co., LtdBy continuously optimizing the nickel plating process and testing methods, the performance stability and reliability of PI nickel plating film have been improved. At the same time, the company actively collaborates with domestic and foreign research institutions to jointly promote the development and application of PI nickel plating technology.

Evaluating the high and low temperature resistance of PI film after nickel plating is a key step in ensuring its stability and reliability in practical applications. Through the comprehensive use of high and low temperature test chambers and other auxiliary testing methods, the performance of PI nickel plating film can be comprehensively and accurately evaluated. The research and practice of Advanced Institute (Shenzhen) Technology Co., Ltd. in this field have provided us with valuable experience and reference. In the future, with the continuous advancement of technology and the expansion of application fields, the performance evaluation methods and technologies for PI nickel plating films will also be continuously improved and developed.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2